We specialise in printing magazines in medium and high volumes.

As a printing house, we offer web and sheet-fed offset printing.

Contact usWhy is it worth it to print magazines with us?

We are flexible when it comes to working with Publishing Houses.

We optimise the price by adapting an appropriate printing technology.

We guarantee stable cooperation, as we are part of a global corporation.

Magazine printing house

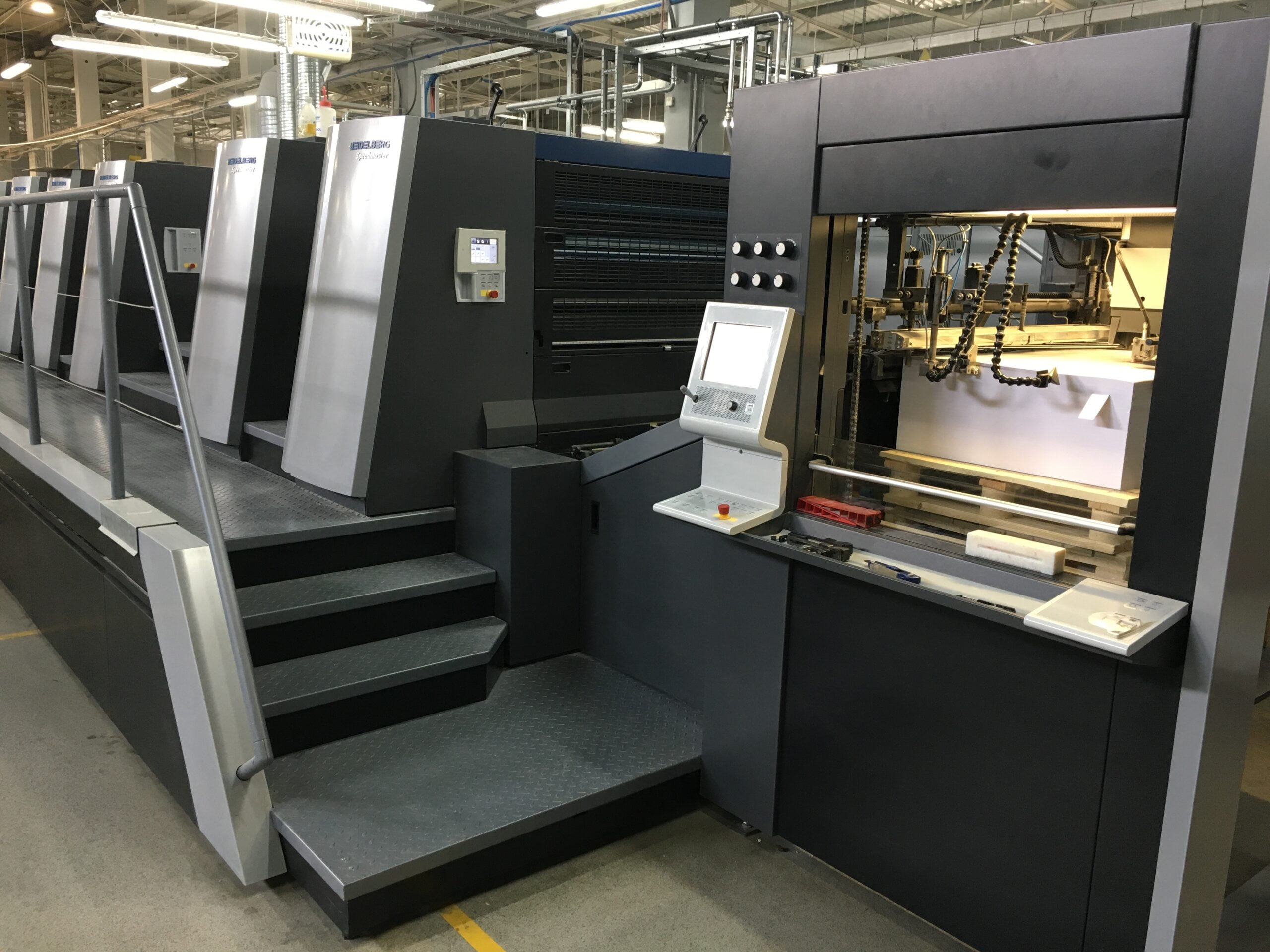

We have been working with publishing houses in the scope of printing magazines and books for over 25 years. We print high volumes on heatset and coldset web printing machines, and at medium volumes, we print magazines on modern Heidelberg sheet printing machines. We offer publishing houses a range of additional services, such as: storage of paper for subsequent issues, securing raw materials and production capacity in the event of increasing volumes, flexibility when sending files or preparing subscription copies for sending out.

Our capabilities:

Sheet-fed printing

sheets/month

Web printing

folded sections/month

Our technology

Heatset web printing

Our printing house is fitted with 4-colour heatset reel machines with a base fold of 16-page A4. We can also work with other formats and various numbers of pages, ranging from 4 to 64. The maximum reel printing speed at our printing house is up to 55,000 folded sheets per hour.

Coldset web printing

For publishing houses for children, which specialise in printing colouring books in high volumes, our printing house offers monochrome coldset print.

Sheet-fed printing

Magazine covers at lower volumes are printed on our Heidelberg Speedmaster XL sheet machines.

Magazine printing house – flexibility in cooperation

We are aware that revenues from advertisements are a significant part of the business of magazine publishing houses. We also know that the advertisements are often sent in at the last minute. We try to set the latest possible time limits for sending files to ensure that a publishing house has enough time to collect the advertisements. In the case of delays in delivering files, we try to adapt the production plan to make sure the delay in the production of the magazine is as small as possible. We always try to find a solution that is the most suitable for a client.

Why is web printing of magazines cheaper?

We opt for web offset printing technology, if:

The magazine’s volume exceeds 10,000 copies. The higher the volume, the lower the price per copy.

Magazine’s format is close to A4 or aligns with the capabilities of our web heatset printing presses in the case of intermediate formats.

The paper is within the range of 45 and 130 gsm.

We care for high-quality production, along with fast print production and cost optimisation.

Printing magazines at lower volumes

We carry out printing of higher volumes on offset sheet printing machines. Our printing house is fitted with Heidelberg Speedmaster XL machines. The subsequent folds of magazines are printed, folded and forwarded for binding.

Printing of prestigious magazines

Sheet machines are also used for printing prestigious magazines. Such magazines have paper with significantly higher weight, exceeding the capabilities of reel machines. Luxurious magazines also come with planned finishing. In some cases, the format of the magazine is not available for reel printing, in which case we also recommend sheet printing.

Paper type vs magazine printing

Depending on the client’s needs, we help to select the appropriate raw material for magazine printing.

For sheet printing, we purchase paper in sheets with the appropriate direction of the fibres. For reel printing, we purchase paper in reels. The waiting time for reel paper is several weeks. This must be taken into account at the initial stage of cooperation. For current issues, after signing a long-term agreement, our paper purchasing specialists pay attention to the availability of raw materials in accordance with the set production schedule of specific issues.

We cooperate with multiple paper manufacturers, both made of wood and without wood. We offer coated and non-coated paper. Coated paper may be glossy, semi-matte or matte at weights adapted to the specific type of machines. For reel print, we offer paper at weights ranging from 42 and 130 gsm, for sheet printing at 60–300 gsm.

Our printing house holds an FSC certificate.

Bindery and services for publishing houses

Booklet

Hotmelt glued binding

PUR glued binding

O-wire

Laminating of single copies

Addressing single copies

Perforation

Labelling individual codes

Automated inserting under the cover

Automated inserting of flat gadgets

Folding

Rounding of edges

Printing and finishing magazines

In order to make a printed magazine more attractive, we recommend to also finish its cover. Elanders printing house offers the majority of finishes, which we prepare by ourselves or using our proven subcontractors.

UV lacquering

UV lacquering is possible on the entire cover, as well as selectively, only for specific components. Selective UV lacquering can be flat or embossed. The combination of a flat cover with glossy, selective UV paper will produce interesting visual and tactile effects through the distinct protrusion of the lacquered features.

Laminating with foil

We offer laminating with glossy, matte, soft touch or anti-scratch foil. Laminating not only makes the printed magazine stand out on the shelf, but also secures and protects the cover. Matte or soft touch foil is often combined with a contrasting, selective UV lacquer.

Hot stamping

With the most prestigious publications, we recommend hot stamping, i.e. the hot application of various types of hot foil, which produces an incredible visual effect. We can select from a range of foil colours – silver, gold, or holographic foils, which have become trendy in recent times.

Embossing

Embossing is typically connected with hot stamping. A selected component of a cover adorned in foil is also embossed or recessed. The reader not only gets a feast for the eyes, but also tactile sensations.

Cooperation with a publishing house

When starting cooperation, you receive a contact for a dedicated employee of the customer service department, who coordinates the work of all the departments of the printing house involved in your projects. Based on the received publishing schedules, the customer service department reserves the time for you in our production schedule for the printing of a specific magazine, and the purchasing department takes cares of the availability of raw material for subsequent issues of the magazine.

Managing a subscription

We offer our clients the possibility of preparing a subscription for sending out – we guarantee selective foiling, addressing and mailing. The foil can be transparent or black. If you have subscribers, our production and logistics department (based on the address database provided by you) will foil, address, prepare for shipping and provide the single copies to the selected postal office.

The shortened cover effect

Printing magazines on reel machines often results in the shortened cover effect. Combining two print technologies – sheet printing for the covers and heatset reel print for the inner pages – results in shortening of the cover by approximately 1 mm, i.e. the cover will be slightly shorter than the inside. This effect is common and practically unnoticeable. Of course, it can be offset by matching the colours of the first inner page to the colours of the cover, however the effect of the shortened cover is barely visible, so publishing houses do not even consider it necessary.

Inserting and printing magazines

When requested, we automatically place inserts on or under the cover. Inserting under the cover is not connected with the need for singular foiling. In the case of inserting flat gadgets or leaflets under the cover, the same production process involves singular foiling of each copy. Inserts placed in a specific place in the magazine require manual labour, which also necessitates an extended production time.

Covers with flaps

To further improve the attractiveness of a printed magazine, you may decide to prepare an edition of the covers with wings. The magazine printing house will propose a cover with a shortened wing (i.e. the cover will be shorter than the inner pages by approximately 3 mm) or a cover with an aligned wing or a wing that is longer than the inserts.

Printing labels

Publishing houses specialising in the offer for the youngest children often make their magazines more attractive with a folded insert with stickers. We also offer the service of printing the labels as an additional element for the magazine or we attach the labels pre-made by the client during the covering process.