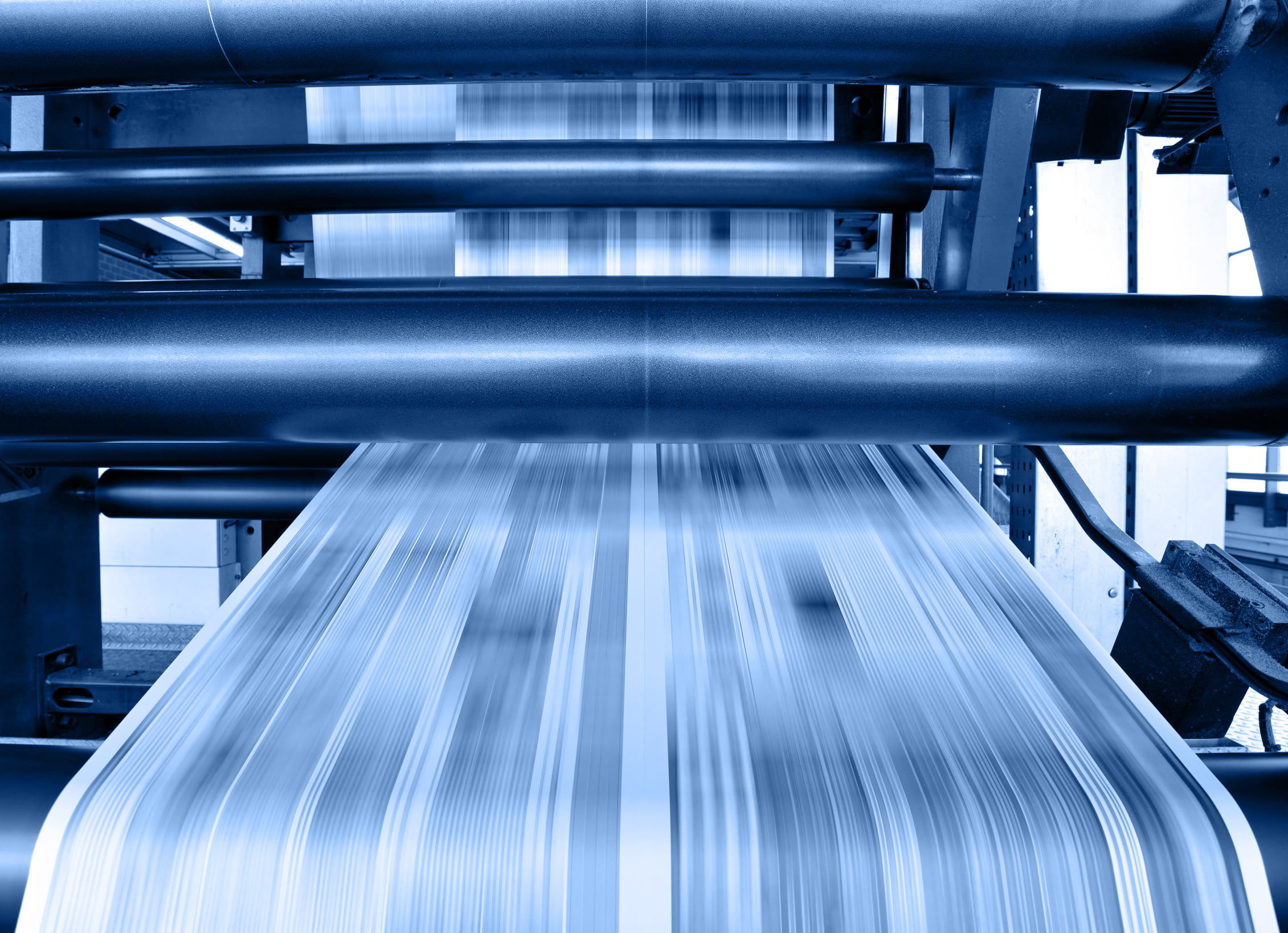

Welcome to the web offset printing supplier, based in Poland.

We offer both heatset and coldset web printing services.

Contact usWhy use web offset printing

Paper purchased in reels is cheaper than sheet paper.

Web printing machines print at a much higher speed.

After reel print, we receive folds ready for covering.

Elanders web offset printing supplier

We have been printing catalogues, magazines, books and manuals for more than 25 years. We specialise in both heatset and coldset web printing. Our experienced team is on hand to assist customers with the selection of the right printing technology for the job requirements. We fulfil orders in high quality and on time – meeting the needs of even the most demanding customers.

Our capabilities:

Coldset

folded sections/month

Heatset

folded sections/month

What makes us stand out?

Flexibility in cooperation

Elanders Printing House is valued by our customers for its flexible approach to cooperation. We understand that publishing houses sometimes have to wait until the last minute to receive advertisements from their clients, which can affect the need to postpone the time limits to return the files. In the case of catalogues, we are aware that the final number of pages in a project may differ significantly from the number of pages originally agreed. Our aim is to adapt to the needs of our clients in difficult situations and to solve the challenges for the benefit of the client.

Comprehensive service

We offer a full printing service for medium- and large-volume prints. For both printing and bindery, we have a wide range of machinery. We have both heatset and coldset reel printers. We also offer sheet printing for non-reeled production. Even the most complex binding or finishing jobs are guaranteed by a well-equipped bindery and a proven base of sub-contractors.

Flexibility in cooperation

Elanders Poland is a part of a global company that is active on a number of continents. Elanders is in the process of global expansion in the areas of supply chain management and print production. The Print&Packaging division has printing plants throughout Europe – in Poland, Germany, the UK, Hungary, Italy and Sweden – as well as in Asia, North and South America. A seamless, long-term relationship is guaranteed by being part of a large, global organisation with stable financial performance.

We opt for web offset printing technology, if:

This is the most cost-effective and efficient printing technology for runs of more than 10,000 copies.

From the moment we receive your files, we are committed to the shortest possible production times, high print quality and excellent colour reproduction.

The format of our publication matches the capabilities of the reel machine. Most machines are set for A4 or near A4, but many other formats are possible.

We accept a waiting period of several weeks for delivery of the roll paper of our choice, or we agree to a paper suggested by the printer that is currently available.

What do we print

Promotional catalogues with spines up to 6 cm thick

Journals in stapled and glued format

User manuals

Books in medium and high volumes

Glued shopping brochures glued at the spine

Journals in stapled and glued format

Schoolbooks and notebooks

Crossword puzzles

Paper type vs web printing

The paper used by web offset printers is purchased in rolls. Reel papers can be covered and non-covered. Covered papers may be glossy, half-matte, silk and matte. The papers also differ by weight. Web printing houses also purchase reel paper at weights between 42 g and 130 g. It is important to remember that the heavier the weight of the paper, the more of a challenge it will be for the folding team. Each of the contributions has its own specific range of permissible weights. When printing a 16-page folded sheet, the maximum paper thickness allowed is 130 g. Please be aware that the lead time for roll paper is several weeks and this time should be taken into account in the project schedule.

Elanders in Poland and internationally

Elanders is part of the international Elanders Group corporation. The Elanders Group operates in more than a dozen countries in Europe, Asia and both Americas. Elanders offers its services in the areas of supply chain management and printing on a global scale. In Poland, Elanders has two production sites and specialises in reel printing, sheet reel printing and digital printing in medium and high volumes. We ship what we produce throughout Europe, Asia and North America.

Web offset printing technology

Web printing is a printing technique in which an image is transferred from a flat printing form, called a plate, to a printing substrate – in this case, a sheet of paper from a roll by means of an intermediate cylinder. Web printing can be done in either a heat-set (i.e. with a drying tunnel – a ‘furnace’) or coldset (i.e. without a drying tunnel) design. With machines capable of printing up to 55,000 folds per hour, this type of offset printing is characterised by its high speed. The need for a sufficiently large print run to make reel print production profitable is a major limitation of reel printing. The minimum web offset printing volume starts at 10,000. It is important to note that, as standard, print enhancements cannot be applied to reel prints unless the press has been upgraded with additional units. Elanders is a high-volume printer. It has four-colour web heatset offset presses and web coldset press for 1+1 printing.

Web printing – heatset and coldset

Variant I

heatset web printing

How it works: the paper fed from the reel passes through the CMYK printing units, where each colour is applied to the paper reel on both sides at the same time. The inked paper reel passes through a drying tunnel where the applied ink dries rapidly using heat. The paper reel is then fed into the folding and cutting unit, which results in a finished fold.

Use: A technology that is used in high-quality printing, such as the printing of catalogues, magazines and brochures.

Variant II

coldset web printing

How it works: The ink is fixed by being absorbed into the paper. The paper reel passes through the printing units from where it is fed into a series of folding machines which bend and trim the paper reel to produce a fold in a specific format. Coldset technology differs from heatset – it does not come with a drying tunnel and the resulting print quality is significantly lower than heatset reel print.

Use: The technology is used primarily for printing instruction handbooks, in-store newsletters, newspapers and crossword puzzles.

Web printing – A4, A5, A6 and other formats

Suppliers of web offset printing services have machines with different technical capabilities, therefore it is necessary to check each time whether a particular job format is possible at a particular printing house. Elanders has equipment with different technical capabilities in its fleet as a high-volume heatset and coldset web offset printer. Heatset web presses have a basic A4 end fold and are mainly used for magazines and catalogues. Of course, the machines can also be adapted to A3, A5, A6 and a wide range of intermediate formats.

Spine glueing – web printing

Besides varying in their folding functions, reel machines also feature distinct binding features, allowing the completion of a final product in a single production cycle. This means we receive a brochure ready for dispatch after the printing process. For example, a product like a store magazine is ready for immediate packaging and dispatch without needing any additional binding, greatly reducing the production timeline. At Elanders, our machines have the ability to glue in the spine of booklets with a volume of 16 pages, 12 pages and 8 pages.

The effect of a shortened cover in web printing

We must be aware of the occurrence of a shortened cover effect when considering the use of roll printing. This is achieved by combining two technologies – a heatset web printing with a drying tunnel for printing the centre sections of a magazine or catalogue, for instance, and sheet-fed for printing the cover, if it is to have a different grammage to the centre sections. During the binding process, the entirety, i.e. the combined cover with the centres, is trimmed evenly to the chosen format. They will begin to absorb moisture from the air and protrude about 1 mm from under the cover after a few days. This is an example of the effect of a shorter cover. This is a very common occurrence and one that the average consumer will not be aware of.

Transverse fibre in web printing

When a fibre runs along the spine of a book or magazine, this is the correct fibre in the paper. With cross-fibre, it looks different – the fibres go across the back of the paper and the paper works in a different way and is more rigid. The cross grain has no effect on the notebook binding, but will be noticeable when the book is used with a glue binding. We can produce formats with both right and cross grain, depending on the settings of the folding machines on a particular reel. This is due to the fact that in roll paper, the fibres always run along the length of the paper web. In sheet-fed printing, we have a choice of short or long fibre paper for the job, but in reel-fed printing, there is no such choice.